What Term Refers to Processes or Activities That Are Completed by Suppliers?

Supply concatenation management (SCM) is the optimization of a production'due south creation and flow from raw material sourcing to production, logistics and commitment to the final client.

SCM encompasses the integrated planning and execution of processes required to manage the movement of materials, information and financial capital in activities that broadly include demand planning, sourcing, production, inventory management and storage, transportation -- or logistics -- and returning backlog or lacking products. Supply chain direction relies on both business strategy, specialized software and collaboration to work.

Because it's such an expansive, complex undertaking, each partner -- from suppliers to manufacturers and beyond -- must communicate and work together to create efficiencies, manage risk and adapt quickly to modify.

In addition, supply concatenation sustainability -- which covers environmental, social and legal issues, in add-on to sustainable procurement -- and the closely related concept of corporate social responsibleness -- which evaluates a company'due south environmental consequence and social well-beingness -- are areas of major concern for today'due south companies.

Benefits of supply chain direction

Supply chain management creates a number of benefits that translate to higher profits, ameliorate brand image and greater competitive reward. These include the following:

- better power to predict and meet customer demand;

- better supply concatenation visibility, risk management and predictive capabilities;

- fewer process inefficiencies and less product waste matter;

- improvements in quality;

- increased sustainability, both from a societal and an ecology standpoint;

- lower overhead;

- improvements in cash menstruation; and

- more efficient logistics.

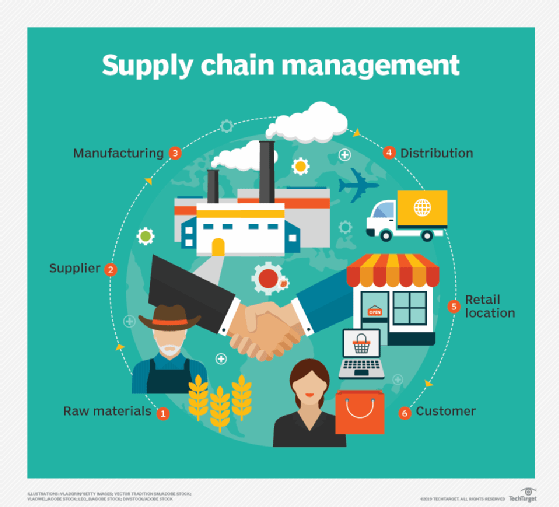

Five stages of supply chain direction

Supply chain management can be broadly categorized into 5 steps or areas:

Programme. Using supply chain analytics and materials management features in ERP systems, organizations create strategic plans to meet customer need for product and avoid a bullwhip issue.

Source. Organizations identify and select vendors that can supply materials in a streamlined and efficient manner co-ordinate to agreements. Supply chain collaboration starts at this stage and is important throughout the supply chain management process.

Make. In this stage, products are manufactured. It includes scheduling the production, testing, ensuring compliance requirements are followed, packing, storage and release. Multiple machines are likely to exist involved, especially for larger companies, and these increasingly use technologies such every bit IoT and AI to work more efficiently.

Evangelize. The delivery stage pertains to logistics and focuses on getting finished goods to consumers, in whatever manner of transportation is needed. As the Amazon effect has grown, especially as a result COVID-19, more focus is on doorstep commitment. Greater emphasis is at present likewise on supply chain leaders working more closely with customer service. Inventory management and warehouse management systems are especially crucial at this stage.

Return. The render stage includes all product returns, including defective products and products that will no longer be supported. This stage as well includes elements from other stages, including inventory and transportation management.

Example of SCM

The nigh bones version of a supply chain includes a company, its suppliers and the customers of that visitor. An case would be: raw material producer, manufacturer, distributor, retailer and retail client.

Virtually supply chains are far more complex and layered. This is why examples of unsuccessful supply concatenation management, where chance is not managed or disruption occurs, can exist so helpful.

Food shortages due to COVID-19 are a adept example of supply chain management gone awry. The food supply chain was disrupted in a number of ways. For case, many restaurants and schools closed to accommodate stay-at-home orders, causing products meant to get to institutional settings in bulk to no longer exist needed. Instead, an exponential number of consumers were eating at domicile, which had different packaging requirements, among other issues. The meat industry also ran into supply chain management disruptions due to issues such every bit COVID-19 outbreaks in slaughterhouses.

The role of supply concatenation management software

Engineering science is critical in managing today's supply chains, and ERP vendors offering modules that focus on key functions within SCM. There are also business organisation software vendors that focus specifically on SCM. A few of import areas to notation include the following:

- supply chain planning software for activities such as demand management;

- supply chain execution software for activities such as day-to-day manufacturing operations;

- supply chain visibility software for tasks such as spotting and anticipating risks and proactively managing them;

- inventory management software for tasks such every bit tracking and optimizing inventory levels;

- logistics management software and transportation management systems for activities such as managing the transport of goods, specially across global supply chains; and

- warehouse management systems for activities related to warehouse operations.

Infor, Blueish Yonder (formerly JDA Software), Manhattan Associates, Oracle and SAP are well-known vendors of supply concatenation software.

The increasingly global nature of today'south supply chains and the rise of east-commerce, with its focus on almost instant pocket-size deliveries straight to consumers, are posing challenges, particularly in the area of logistics and demand planning. A number of strategies -- such as lean manufacturing -- and newer approaches -- such equally demand-driven material requirements planning -- may prove helpful.

Engineering -- peculiarly big data, predictive analytics, IoT technology, supply chain analytics, robotics and autonomous vehicles -- is likewise being used to help solve modernistic challenges, including in the areas of supply chain risk and disruption and supply chain sustainability.

As just two examples, IoT tin assist with transparency and traceability to assistance boost nutrient quality and prophylactic by using sensors to monitor the temperature of perishable food while it's in transit. And analytics can help determine where to put smart lockers in densely populated areas to cut the number of unmarried-item deliveries and lower greenhouse gas emissions.

This was terminal updated in November 2020

Continue Reading Near supply chain direction (SCM)

- Eight keys to supply concatenation sustainability

- vii supply chain management fundamental terms yous need to know

- The essential guide to supply chain management best practices

- An manufacture analyst explains how SCM software tin better resiliency

Dig Deeper on Supply chain and manufacturing

-

Gear up a supply chain disaster recovery programme

-

Guide to supply concatenation management

-

contrary logistics

-

supply chain

Source: https://www.techtarget.com/searcherp/definition/supply-chain-management-SCM

0 Response to "What Term Refers to Processes or Activities That Are Completed by Suppliers?"

Post a Comment